Biosolids Management Solutions

Transform Biosolids into Valuable OurCarbon

Addressing biosolid accumulation and disposal challenges with advanced solutions in biosolids management that transform wastewater sludge into OurCarbon – a valuable, carbon-negative resource.

Addressing Biosolid Accumulation and Disposal Challenges

New Zealand and Australian councils and industrial manufacturers face critical issues with biosolid accumulation and waste disposal. With landfills becoming increasingly costly, carbon-intensive, and in some cases refusing to accept biosolids, finding sustainable solutions is more urgent than ever.

FILTEC, in partnership with Bioforcetech, offers innovative biodrying and pyrolysis technology to transform biosolids into valuable OurCarbon (a unique biochar), alleviating disposal challenges and supporting sustainable management practices.

OurCarbon

Converting Waste into a Valuable Resource

Transform Your Biosolids into Value

A Carbon-Negative Resource from Waste

Each year, over 1 million tons of biosolids from wastewater treatment are landfilled, leading to methane emissions and environmental waste. FILTEC’s BioDrying process, powered by our partnership with Bioforcetech, transforms this biosolid waste into OurCarbon – a carbon-negative material that significantly reduces Global Warming Potential (GWP).

OurCarbon is used as a colorant in inks, dyes, and coatings, as an additive in polymers and foams, and as a replacement for concrete aggregates. It offers a sustainable alternative that lowers carbon footprints and replaces fossil-dependent materials.

Benefits of BioDrying Solutions

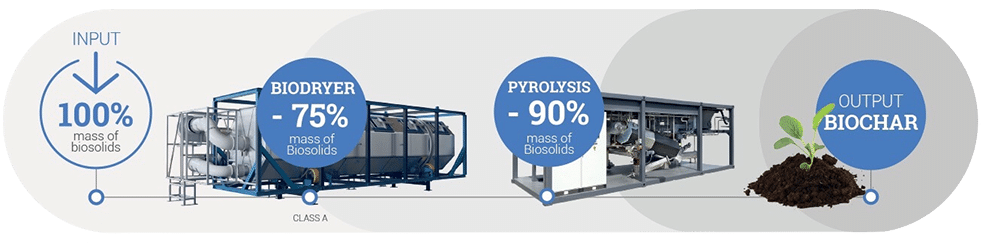

- Up to 90% Less Volume Reduction of Biosolids and Organic Waste

- 90% Less Trucks and Reduced Landfill Usage

- Up to 100% Less Energy Consumption

- Integrates Easily with Existing Wastewater Infrastructure

- Improved Environmental and Social Impact

- Low Operational and Maintenance Costs

The OurCarbon and BioDrying Process

BioDrying is an advanced, efficient heating process that reduces the moisture content and overall weight of biosolids. Our modular drying system cuts thermal energy consumption by 50% compared to traditional gas-heated systems like belt dryers, making it an effective solution for sustainable biosolids management and producing valuable OurCarbon.

Our Solutions for Biosolids Management

BioDryer System

The BioDryer system is modular, offering independent or combined operation to meet diverse drying capacity needs efficiently. With simple plant design and rapid installation, scalability is guaranteed.

Each unit can dry approximately 1,000 tons of biosolids annually, enhancing solid content from 17% to 90%. The BioDryer ensures Class A biosolids with minimal operations and maintenance for larger production capacities.

Pyrolysis System

The Pyrolysis system offers a compact and modular design, fitting within a 40-foot container. The fully automated system streamlines biosolids management processes, reducing manual labour and biosolid disposal costs.

Designed to process various organic materials including biosolids, nut shells, wood chips, the Pyrolysis system accommodates a range of waste streams. Integrated with the BioDryer system, it forms a dual biosolids management solution.

BioDryer System Design

Materials

Constructed with stainless steel, the BioDryer body ensures durability, while the air system, crafted from recyclable plastics, reflects our commitment to sustainability. We source the system from a leading global supplier, guaranteeing reliability and performance.

Performance

The BioDryer delivers exceptional performance and has been engineered to operate at peak efficiency. The BioDryer consumes less than 35 kWh/ton and 1.2 MMBTU/ton, ensuring both cost-effectiveness and sustainable operation.

Automation

The BioDryer is controlled by smart Plexus Software, offering automated reports, predictive maintenance, and self-adaptive algorithms. Experience Industry 4.0+ capabilities from day one, streamlining operations and maximising productivity.